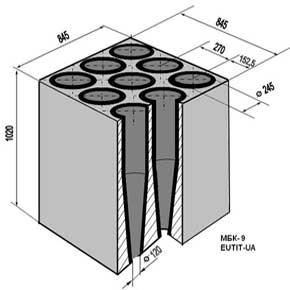

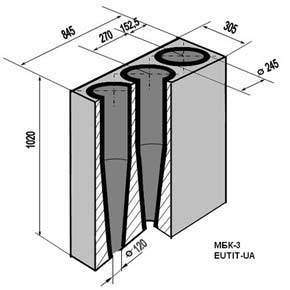

Multicyclones MBK

Modular combined multicyclone separators MBK-3, MBK-9 are designed for installation in treatment facilities of sintering machines in ferrous and nonferrous metallurgy for the purpose of dust elimination from the gases produced during sintering.

The modular combined multicyclone separators consist of stonecast elements, and the cyclone separator itself consists of top – cylindrical and bottom – cone-shaped parts. The joining place is ground, and then elements are stuck together with special composition on the basis of epoxy resin. The seam between parts makes no more than 0.2 mm.

|

|

Operating experience of the combined multicyclone separators in comparison with the separators with working elements made from cast-iron has provided significant positive results. Small rate of stonecast element effective surface wear (hardness of stone casting is 4 times higher than of cast iron) provides long-term stability of parameters of a gas stream and high separation efficiency of gas. Hydraulically smooth surface of a cast stone (coarseness is 0.04 mm that in 3-4 times lower than of cast iron) improves a dust flow by cyclone separator walls raising its efficiency. Absence of a dielectric stress on a stone element excludes adherence of parts with magnetic properties which is characteristic for cast-iron elements. Flow area decrease of the cyclone separator with stonecast working elements has lead to increased speed of passing through gas to an optimum value of 5-6 m/s that also positively influences separation efficiency of gas.

Results of dust and gas measurements in sinter plant NK GOK (Novokrivorozhsky mining-and-processing integrated works, "Krivorozhstal") where modular multicyclone separators made from cast basalt are used, have shown that their efficiency, in comparison with the cast-iron, is 12 % higher, and their endurance has increased in 2 times and makes 8 years.

Modular combined multicyclone separators with working elements made from cast basalt are manufactured by LLC "EUTIT-UA". Such cyclone separators are successfully operated in OJSC "Enakievsky metallurgical plant", Closed Joint-Stock Company "Dneprovsky integrated iron-and-steel works named after Dzerzhinsky", OJSC "Alchevsky integrated iron-and-steel works", OJSC "Ilyich integrated iron-and-steel works of Mariupol", OJSC "Krivorozhstal".

| Трубы футерованные | Кислотоупорный кирпич | Термостойкое литье | Циклоны |

| Плитка базальтовая | Футерованные отводы | Желоба | Мультициклоны |

Казахстан: |

+7(701) 780-30-82 ktpkz@mail.ru |

Армения: |

+3(749) 443-53-91 armecofuel@gmail.com |

Адрес: г. Караганда, ул. Камская 8 |